OUR FACILITIES

ROTELU has a manufacturing area of 3600 m2 where 2250 m2 are covered, with the following sizes:

- Maximum height under hook 6.7 m

- Maximum diameter 5,0 m

- Maximum width: 7,9 m

- Maximum length: 75 m

LIFTING CAPACITY AND HANDLING

- 2x Crane bridges of 16 Tons

- 5x Crane bridges of 10 Tons

- 2x Crane bridges of 5 Tons

- Trolley of 20 Tn

PLATE ROLLING CAPACITY

- 1x Rolling machine Faccin 4HEL 3145

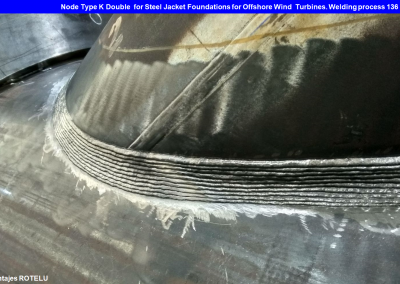

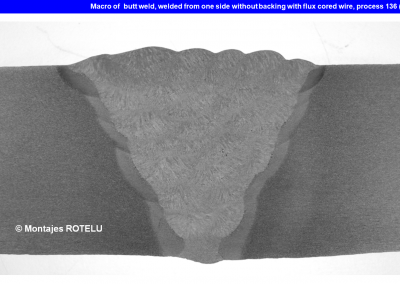

WELDING PROCESSES

BASE MATERIALS ACCORDING TO ISO/TR 15608

- Group 1 (carbon steel), subgroup 1.1 & 1.2

- Group 8 (stainless steel), subgroup 8.1

- Dissimilar joints subgroup 8.1 to 1.2

WELDING EQUIPMENT

- 9x Multi-Process Welding Machines (111, 131, 135, 136 ,138 y 141)

- 7x Semiautomatic Welding Machines (131, 135, 136, 138)

- 2x Columns with submerged arc (121) up to 5 m diameter

- Roller positioners up to 20 Ton

- 1x Induction Machine for Preheat

QUALIFICATIONS OF WELDING AND TESTING STAFF

- Qualified welders according to EN ISO 9606-1

- Qualified submerged arc operators according to EN ISO 14732

- MT and UT Inspectors Level II according to EN ISO 9712

- Welding Coordinator (IWE) according to EN ISO 14731

ROTELU is located close to its main suppliers of Thermal Cut, Machining, Heat Treatment and Passive Treatment.